More and more concerns manufacturing household appliances began to use the inverter motor in the washing machine and to conduct a wide advertising campaign on this subject. It is interesting to find out whether the final consumer really gets an improved product or do companies simply simplify the model using more innovative production technologies and earn extra income on this?

Figure 1. Why is it profitable to buy an inverter washing machine

Design features of inverter machines

In all washing machines with an asynchronous or commutator motor, movement from the shaft to the drum is transmitted through the belt. Therefore, the characteristics of such devices indicate the type of drive - "belt". This indicates a complex design, including: pulleys of the drum and the motor shaft, belt, fasteners.

Figure 2. Conventional motor with a pulley

The situation is different when using an inverter motor with direct drive. It eliminates the need to use the above components due to its installation directly on the tank of the washing machine. The motor shaft is the drum shaft, hence the smaller number of bearings in the system. This type of design was first proposed by LG to its customers, promising a ten-year product warranty.

Figure 3. Attaching the inverter motor to the tank

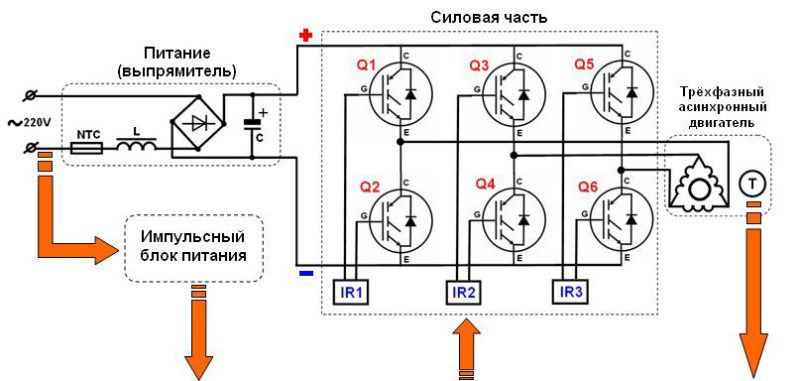

The control of the power part of the inverter motor is similar to the principle of controlling asynchronous motors, because it itself is a three-phase brushless motor that is powered by direct current. The control circuit is based on a voltage inverter. The latter is able to give pulses with an amplitude from zero to 120 V and with a control frequency of up to 300 hertz.

Following LG and other concerns began to widely introduce technology using inverter motors, but not it's always direct drive. Many models of modern washing machines are equipped with stepper (inverter) motors, traditionally located under the tank.

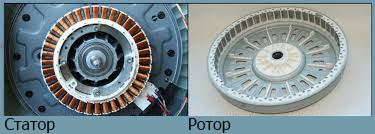

Inverter motor device

To understand how reliable the design of the motor itself is combined with the shaft, it is worth disassembling its “iron”. This will help to draw adequate conclusions regarding the quality of washing machines with inverter motors installed. The mechanism consists of:

- A stator assembled on coils wound around cores made of electrical steel. The cores themselves are soldered into a polymer base, which is directly attached to the tank (fixed part). A total of 36 coils, their windings are connected according to the "star" scheme.

- A rotor (in the shape of a bowl), the base of which is made of steel. Permanent magnets in the amount of 12 pieces are glued along the perimeter of the cylinder. The rotor is attached to the drum shaft through a plastic sleeve with splines. This is done in order to exclude the possibility of magnetization of the shaft.

- Hall sensor. Using it, the positioning of the rotor relative to the coils is monitored.

Figure 4. Inverter motor device

Whole work washing machine motor controlled by a combination of opening, closing and partial unlocking of power keys collected on transistors. They change the direction of current flow on the phases of the coils and the magnitude of the magnetic flux in them. The inverter controls the operation of the keys using pulse-width modulation.

Figure 5. Engine control circuit

As can be seen from the design, the motor is simple and does not even contain bearings, they are common to it and the drum shaft.

Causes of Malfunctions and Diagnostics

Despite the simplicity of design and the apparent reliability of the components of washing machines where an inverter motor is used, they also fail. The most common reason is a malfunction in the Hall sensor. In LG machines, such a malfunction is indicated by the “SE” error code on the digital display.

Figure 6. Hall sensor

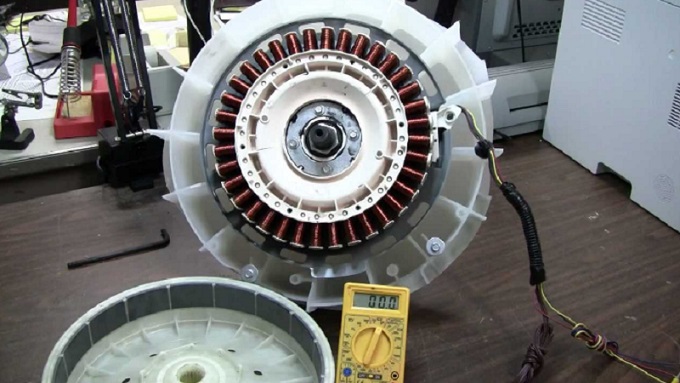

The problem can also be diagnosed by focusing on the metallic rattling sound emitted by the device. All this is accompanied by a stop of the rotor, its inappropriate behavior. Replacing a suspected element malfunction with a known-good one is the only way to confirm their concerns. The difficulty is that it is impossible to diagnose the motor outside the washing machine, except to ring the phase windings with a digital multimeter.

Figure 7. Checking the coils with a multimeter

Malfunctions in the inverter can also be the cause of a failure, but it is not possible to identify such a malfunction without special equipment and knowledge in electronics.

How to replace the engine and connect it to the washer - read the link on the website.

Pros and cons of new generation washing machines

What real benefits can a consumer get from buying an inverter washing machine? Undoubtedly, these are:

- Long term warranty. LG gives up to 10 years to work equipment.

- Noise and vibration reduction. Manufacturers claim that due to the absence of rubbing elements (brushes, belt), the machines work almost silently.

- Saving electricity. Higher efficiency systems are obtained due to minimal losses in the transfer of energy from the engine to the drum.

- Simplicity of design. There is almost nothing to break, modules for replacement are always available.

- Lack of brushes. The most vulnerable element in collector engines, which has a limited resource.

There are few shortcomings, but they are still solid:

- The price of technology. If we take washing machines similar in parameters, but having a different type of motor, then inverter models can cost 30% more.

- Sophisticated engine management system. If it fails, the repair will not be cheap. A similar situation with engine failure.

Should I buy an inverter model?

It is impossible to unequivocally answer this question, it all depends on the needs of the person purchasing the washing machine, but you can conduct a small analysis of the material presented and think:

- Why is silence necessary? For small apartments where it is not possible to place the equipment indoors, a silent washing machine is ideal. The washing process will not distract from more important tasks.

Figure 8. Quiet machine does not interfere with sleep

- Why is silence necessary? For small apartments where it is not possible to place the equipment indoors, a silent washing machine is ideal. The washing process will not distract from more important tasks.

- How much energy can you save? Experts say - no more than 5%, because the main costs are spent on heating water with electric heaters, and not on the engine.

- How quickly do brushes on a commutator engine fail, if we consider this version of the model? Depending on the intensity of use of the equipment, the term for producing high-quality brushes can be up to 10 years - this is not enough.

- An impressive guarantee for an inverter motor - is it important? Undoubtedly, if there are no other factors that destructively affect the technique, for example, hard water or sudden changes in voltage. All this can negate the efforts of engineers to extend the life of the machine.

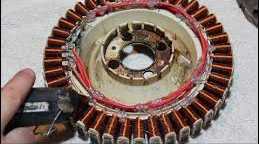

- A simplified arrangement of the engine on the drum shaft what gives? First of all, the absence of additional loads and a longer resource of mechanics. The only negative is the direct proximity of the electrical part to water. It is worth the gland to fail and no one will insure against burnout of the windings. Such situations have already been encountered in practice.

Figure 9. Disruption of the winding due to water

Conclusion

When choosing a washing machine for the home, it is important to consider the totality of the parameters of a particular model. It will be a shame to spend a hefty amount on modern technology and not get the desired result in the work. Therefore, before you go shopping, you should not be lazy to draw up a plan of tasks for the future assistant and study at least the small model range that manufacturers offer. The task of the washing machine is, first of all, to qualitatively wash the laundry!

Figure 10. Important washing quality