Syndrome of “bird nesting” is a problem of a sewing machine, which everybody who is engaged in sewing has encountered at least once. If during work, instead of a straight line, you saw a bunch of threads, and the needle moves with difficulty or is completely stuck, then to find out why the threads are so often confused in a sewing machine, read our article.

This is what confusion looks like

In most cases, you will not need to call a specialist for repairing sewing machines. It doesn’t matter if you have a mechanical machine or an automatic one, old or new. The principle is the same everywhere, but you can learn about the device of your machine from the instructions.

We recommend that you read the article: “Why in sewing machines can loop the bobbin thread«.

Why is a thread tangled on a sewing machine?

Here are a few common reasons this can happen:

- the thread is incorrectly threaded;

- the upper and lower threads are stretched unevenly;

- the needle does not match the thickness of the thread or is not inserted correctly;

- mechanical damage.

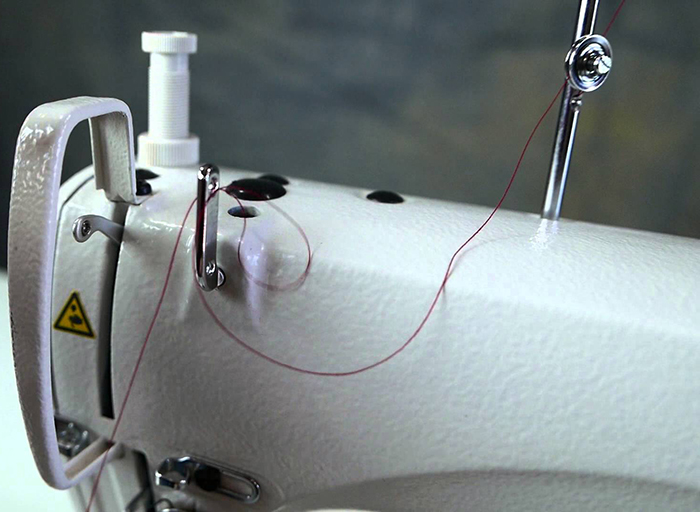

Incorrectly threaded thread - The most common cause of confusion. First of all, check if you did it correctly. This applies to both threads. Refill it carefully, if necessary referring to the instructions. If at some point you made a mistake, correct it and the problem will be solved.

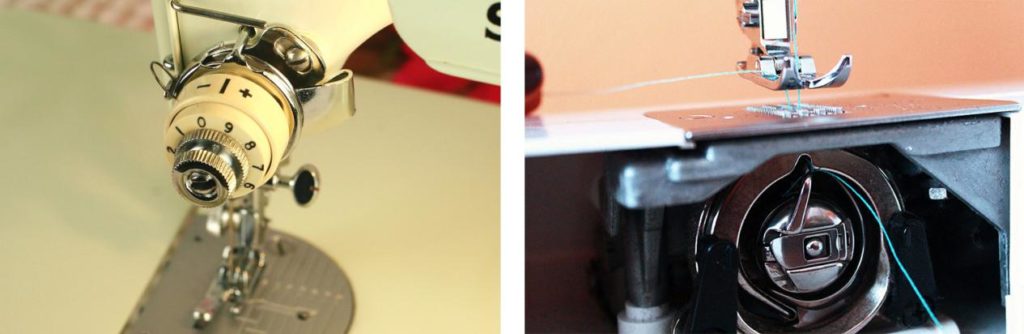

Tension adjustment

Often confusion occurs due to the uneven tension of the threads: the upper one is adjusted with correcting plates, the distance between which is determined by the switch mounted on the machine body, and the lower one in the bobbin case.

Upper adjuster and lower

- The smaller the distance between the plates, the stronger the tension of the upper thread

To adjust the tension of the lower thread you will need a screwdriver. First you need to raise the foot and remove the needle plate. There is a screw on the bobbin case, turning it with a screwdriver you can increase or decrease the tension of the lower thread.

If the bobbin thread does not hold the upper thread and creeps up during sewing, then in the best case, the stitches will look untidy, and in the worst, they will become tangled. In this case, you need to increase the tension of the lower thread by sliding the plate. To do this, tighten the screw tightly with a screwdriver on the bobbin case:

The arrow shows the screw for adjusting the tension.

After that, make a few test lines. If everything is in order, you can proceed to delayed sewing.

- Threads can be confused if the bobbin is not in its place. If everything is done correctly, then when you place the bobbin in the shuttle you will hear a characteristic click

If the machine is correctly charged and everything is in order with tension, then a malfunction may be due to a machine malfunction.

Confusion can occur due to defects in the shuttle. With this problem, it is advisable to contact a specialist in repairing sewing machines.

But you can get rid of them yourself if it's just a small burr. Remove the needle plate and see what the thread clings to. Turn the wheel with your hand towards you and if the lower thread does not pop up, then carefully pull out the shuttle and see if it hooks on it. This may occur due to the appearance of burrs, which should be carefully cut with a scalpel (or nail file). Try to leave a smooth transition after them, along which the thread can slide without interference.

After installing the shuttle back, check the progress of the lower thread. If everything is in order, put back the hook with the bobbin and the needle plate.

What else can cause confusion and how to avoid it?

- If the thickness of the threads does not match the thickness of the needle, then the lower thread will most likely be confused;

- Slight pressure on the fabric. It should be adjusted according to the thickness of the material;

- The threads are left twist (S) and right (Z). For sewing machines it is better to choose those that are twisted to the left;

- It is desirable that the threads on the bobbin be wound from the upper spool;

- The needle is inserted incorrectly. To fix this problem, remove it and reinsert it all the way to the left flat. Make sure the inlet is exactly centered and tighten the screw.

- The needle is dull. In this case, it must be replaced with a new one;

- If you have been using the machine for more than one year, then it is worth treating the parts with oil, often problems arise due to damage to the parts by time.

A few words in conclusion

Do not use low-quality or old threads. If they are of poor quality, then you will often encounter confusion and cliff. And the appearance of the finished lines will have a miserable appearance.

You should not choose “rare” threads for sewing

If you cannot handle the tension, check for foreign objects in the sewing machine. To do this, take a toothpick and walk along the path of thread movement.

When changing the thread (for example, from X / B to synthetic, smoother and thinner), you will need to reconfigure the tension. Otherwise, you will again have to face the appearance of confusion due to improper tension.

In our article you can also find out why sewing machine tears a thread.