Sewing machine operation may not be satisfactory for a long time. But at some point the upper thread often breaks, and the quality of sewing decreases. In this case, you must resolve the problem. There may be several reasons why the sewing machine tears the upper thread.

To find out why the upper thread often breaks in your sewing machine, consider possible problems and how to solve them. First, we check the correctness of the threading of the upper and lower threads in the machine. We make sure that dust or other foreign objects do not interfere with the operation of the mechanisms.

Tension regulator malfunction

The canon spring, the main element of the thread tension regulator, can be twisted too much. In order to correct the situation, it will be quite enough to simply weaken it by twisting it a little.

If this part was disassembled for any reason before a malfunction was identified, it may turn out that it was simply not assembled correctly. It is recommended to completely disassemble it and reassemble it. In case of jamming of the canonical spring, it is necessary to release the next turn so that it becomes possible to move the upper thread easily.

Under low tension, when the control nut is not tightly screwed in, loops may form. They interfere with the normal course of the line, falling into the shuttle groove. At the same time, the sewing machine tears the thread. To solve the problem, you need to tighten the nut on the tension regulator, which will tighten the spring.

Upper thread tension adjuster on the housing

Advice! The correct assembly of the tension regulator itself must be checked according to the instructions for the sewing machine, as different models can have their own characteristics.

Poor thread quality

Often a low-quality thread is visible with the naked eye - it has a different thickness along its length with thickenings, knots and other defects. In this situation, there can only be one piece of advice - the upper thread that has defects must be replaced.

Good stitching

Needle problems

The quality of the needle and the correct installation are very important for the good operation of the sewing machine.

Incorrect installation

The sewing machine needles have a special groove along their length. Regardless of the brand of the sewing machine, the chute should be turned in the same direction as the thread guide. With the correct location of the needle, the thread provides free play and it does not break. The needle should be fully inserted and well fixed with the screw.

Needle defect

The needle may have sharp edges in the threading hole. It is not realistic to work with such a needle, it should be replaced with a quality one. Otherwise, when the thread passes, it will be cut.

For your information! The most common causes of upper thread breakage include defective needles and threads.

Wrong needle selection

Sewing machine needles have different thicknesses. They can be oriented to work with certain materials, for example, leather, denim. If the needle was chosen incorrectly, the thread may also break. Therefore, it is so important that the thickness and appearance of the material match the selected needle and thread.

You can also find out why threads in cars begin to get confused.

Pusher installation incorrect

This situation may occur if the disassembly and subsequent assembly failed. Pay attention to how the part is installed. When the tapered part is oriented towards the lever, the part should be rearranged. If the pusher is lost, it will have to be replaced with a new one.

Correct installation of the pusher

The problem with the bobbin case

A bobbin case may cause several problems.

Bobbin case

Notch on the surface

The defect sometimes occurs with a long service life. During the operation of the sewing machine, a recess appears on the part as a result of continuous sliding of the thread at this place. To fix the problem, you must replace the bobbin case or level the surface with tools.

Incorrect selection of parts

If the bobbin case is skewed and loosely attached to the screw, it should be replaced. All parts must be selected in accordance with the model of the machine.

The bobbin case is not adjusted

There is a small screw on the bobbin case. How tightly it is tightened has an effect on whether the upper or lower thread breaks or not. The bobbin case must be removed, make sure that it is not clogged, loosen it a bit and set it back into working position.

Advice! You should always take the upper thread tension control first, and deal with the bobbin case only if the first method did not help.

Needle plate defects

If the sewing machine is used for a long time, and the needle is not properly centered, periodic needle hits on the plate are possible. Defects in the form of notches left as a result of this can lead to line breaking over time. In this case, the thread breaks, and the quality of work decreases.

The needle plate must be operational

The way out will be:

- proper installation of the needle so that it passes strictly into the designated hole and does not touch the needle plate;

- replacing the plate or sharpening it in order to eliminate existing defects.

Important! Do not use jagged and damaged needles.

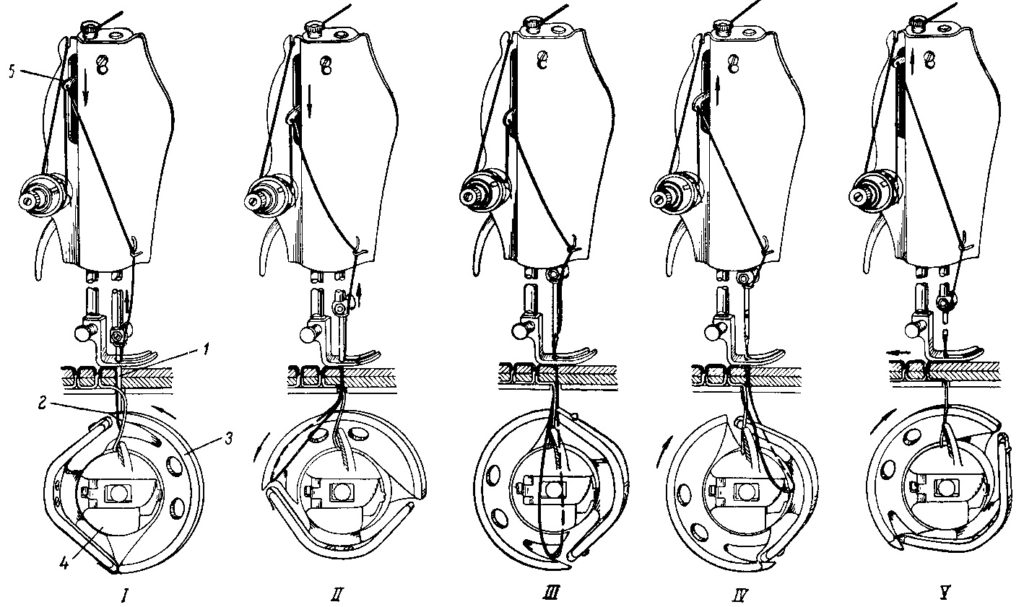

Shuttle Failure

The shuttle is one of the most important parts of the sewing machine. Its incorrect installation may be one of the reasons that the upper thread tension is broken, and it breaks.

Shuttle Sewing Machine

Advice! Make sure that the surface is not damaged and meets the necessary requirements.

If there is a mismatch in the work of the shuttle and the needle, the sewing machine can also tear the upper thread. It is necessary to reinstall the crank in the correct position and fix it.

We also recommend reading which models are produced by overlock manufacturers.

Other problems

There are other circumstances that can affect the quality of the line and cause the thread to break at the most crucial moment:

- If all possible causes are sorted out, but the sewing machine still tears the thread, it is possible that it has not been subjected to preventive lubrication for a long time. Parts and assemblies should be well oiled to move easily and not tear the threads in the sewing machine.

- Make sure that the thread flows evenly from the spool installed on the sewing machine - it is not tangled on the spool or on the holder on which it is installed.

- The upper and lower threads should be the same thickness.

- A dull or deformed needle must be replaced without any regret.

- Thread the machine must be carefully, without missing any holes and grooves.

- Having coped with the problem of breakage of the upper thread, you may encounter such a malfunction in the work as looping the stitch. This sometimes occurs due to excessive loosening of the tension adjuster. Or in the case when they forgot to insert a spring pressing the discs.

By checking each of the possible causes, you can almost certainly find the source of the problem yourself adjust the sewing machine. In case of complex breakdowns, you may need to contact the master, who will fix serious malfunctions and arrange the work of the sewing machine.

You can also read on our website. article about overlock seams and their differences.