When buying a sewing machine, a gigantic amount of information about the capabilities, safety and durability is collected and data on the initial setup of the machine is missed. Having prepared the workplace in advance, having performed the necessary manipulations, and having installed the bobbin, suddenly the quality of the line does not correspond to the declared one. The main thing to do is calm down and follow the plan.

Determine the type of sewing device

According to the general principle of technology separation, three types are conditionally distinguished:

Figure 1. Mechanical sewing machine

- Mechanical models. The method of operation of the unit is manual exposure to all elements of the machine, which saves electricity. The device can sew only straight stitches. Due to the ease of replacement of components, such machines are easy to repair, and in fact they rarely break.

Fig 2. Electromechanical machine

- Electromechanical combines working from an electric drive located in the pedal. Machines perform many different types of seams, sew buttons, darn, and create loops.

Fig 3. Programmable sewing machine

- Sewing computer. Such a device has in its functionality unlimited potential from performing complex embroidery to obtaining advice on the selection of fabric or the strength of the puncture. If the house is unstable in the flow of electric current, be sure to purchase a voltage stabilizer so that power surges do not burn the computer board.

Of course, the higher the capabilities, the more expensive the machine, the more complicated the instructions for it, a different level of assembly, but this is justified by the miracles of sewing that a programmed unit is capable of.

We recommend reading on the website: “How choose the right thread for overlock«.

Identify the working elements of the sewing machine

It is necessary to update knowledge about the main working bodies of the sewing machine, especially if you have never sewed before:

- Needle or set of needles.

- Needle holder.

- Needle plate (conveyor).

- The foot is a metal part located under the needle holder, similar to a small ski. In the lowered state, presses the fabric.

- Lever for raising and lowering the presser foot.

- The reel seat is a rod with a rounded base, usually located at the very top of the machine, designed to hold the reel.

- The thread guide is a metal geometrically curved formation at the top of the machine, located near the reel seat. The main purpose is to guide the upper thread to the bobbin winder.

- Stitch knob.

- Bobbin.

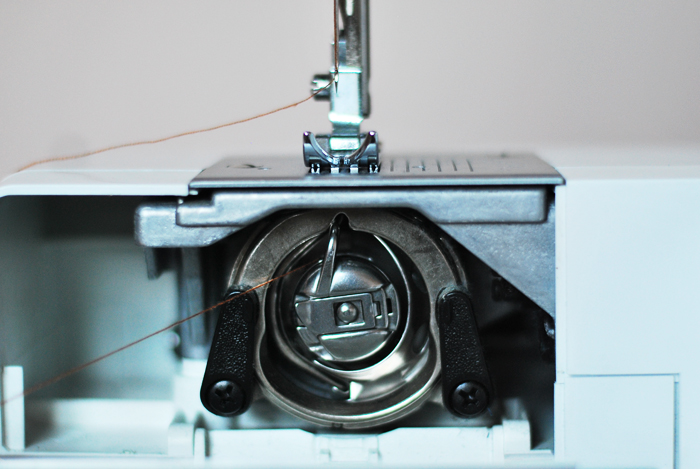

- Shuttle device inside the machine.

It is from the coordinated work of the elements of the sewing unit that the beauty of the obtained seam depends. Check for spare parts and accessories: special foot sets, needle set, bobbins, darning plates, screwdrivers, etc.

The first setting of the sewing machine

When starting work on threading threads into the machine, turn it off, put the foot in the upper position, and use the handwheel to raise the needle. Despite the huge variety of sewing machines using, for example, several needles for sewing, the principles of operation have remained the same:

- Threading the upper thread. Follow the instructions for your sewing machine.

- Threading the bobbin thread. Take the instructions, and carefully follow the attached diagram.

The verification of the correctness of both tucked threads is carried out by lightly pulling them 5-8 cm to the side, and laying them on the foot in a straightened state. The sewing machine is ready to go.

Figure 4. A sewing machine prepared for work, the ends of the silk are brought out.

Read also how to customize sewing machine.

Stitch defects or why the bobbin thread is sewn (stitch, seam) in the sewing machine

Even when the sewing machine is correctly tucked in, there are nuances that affect the correct execution of the horizontal seam. The lower thread forms an air stitch loop on the following factors:

Figure 5. Loop formation

- Unevenness of wound thread in the bobbin. A similar problem occurs when manually winding on a bobbin, without using a special device of the machine. The unevenness of the twisted thread contributes to a similar uneven unwinding, which is why the sewing machine does not give the correct and beautiful stitch, but loopes. To solve the problem, unwind the bobbin and, finding a special device for uniform winding on the bobbin at the sewing machine, use it.

Figure 6. Evenly reeling bobbin

- Low thread tension. It is necessary to check the bobbin cap and the fit of the plate, then adjust the shuttle device. When changing the thickness of the thread, you need to adjust the shuttle device. Shake the cap with the bobbin in your hand, observing the sticking thread, if it flew under its own weight, adjustment with a screwdriver will help to eliminate the defect in the fit of the plate.

- Excessive upper thread tension. Find the tension regulator that is used every time you change the thickness of the fabric, size and quality of the threads. Following the order of numbers on the knob, twist the bezel, loosening it.

- Sometimes looping of the bobbin thread is caused by slipping on a material not intended for sewing on this machine, using non-recommended threads to avoid such situations, read the instructions before using the machine.

- Worn bobbin or its not quality. If the above methods did not help to find out why only the bobbin thread in the sewing machine winds, then the problem is a non-working bobbin. Replacing the bobbin, check the operation of the machine, if the correct sewing is achieved, then the problem is fixed.

See also why in sewing machines confused thread.

Stitch defects or why the upper thread (stitch, seam) in the sewing machine

If loops form on the underside of the fabric, then the upper thread winds around, according to the following factors:

- The weakened position of the upper thread, up to sagging. Find the tension regulator, and, following the order of numbers, increase the tension, check that the needle number and thread size match.

- If there is an excessive tension of the upper thread, to manipulate to weaken it, the reverse of the above measures.

- The accumulation of fibers of tissue residues, pieces of thread in the tension regulator, which causes the upper thread to loop. Do not forget to regularly clean the regulator washers and at the same time clean the shuttle mechanism.

- The upper thread winds, also due to the wear of the bobbin case spring, which is usually not repairable; a new part is replaced.

Fig. 7. Cap wear that cannot be repaired.

- If you find a visible malfunction of the yarn guide, you must call the wizard.

There are many reasons for the appearance of an uneven seam stitch, but most of them appear due to irregular preventive care. Carefully read the instructions when using the machine for the first time or if you need to update the information, thread the threads correctly and lubricate the moving parts of the machine, as well as clean them regularly. If the performed manipulations do not bring the desired effect in terms of improving the beauty and correctness of the line, you should call the wizard.

You can also read on our website: "Overlock seams: what are and how are they different. ”