Hot water in the house is a common property of most citizens in developed countries. Her absence makes life less comfortable. Well-maintained houses are equipped with piping with hot and cold water. If a residential property has a single water supply option, for example, a water pipe, a well or a well, it is possible to install electric titanium.

The boiler will provide the house with hot water at any time of the day. But there is one caveat when installing it - the need for a water seal. Ignoring the rules can lead to breakdown of an expensive device and damage to the interior decoration. To avoid disastrous consequences, we will consider how to independently install a check valve on an electric water heater and its functions.

Water heater check valve

The principle of operation and the device check valve

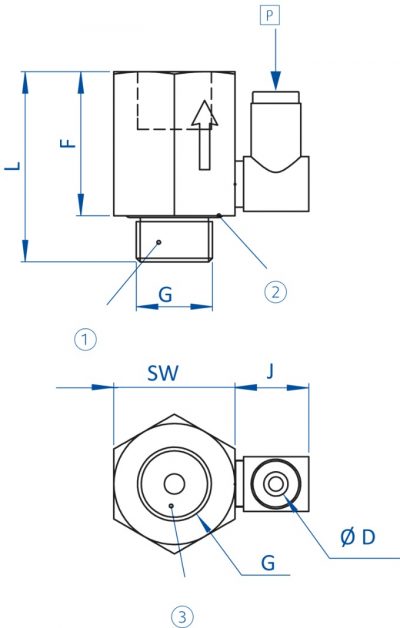

The non-return valve is a water lock that contains two chokes in its body located perpendicular to each other. In the central cylinder, which is connected in series to the trunk, the main throttle is installed. Its function is to prevent the outflow of water from the boiler into the water supply system.

The incoming side is equipped with an external threaded connection (fitting), popularly called "dad". This edge is most suitable for connecting a flexible water hose to it, which is practiced in most cases.

The opposite side is equipped with a clutch (nut), in common people - “mother”. This edge is the outlet of the device and is screwed onto the boiler fitting. It is necessary to put a water lock on a branch pipe of cold water.

Perpendicular to the axis of the device is another valve. It is smaller. However, the spring of this inductor has a more powerful device. Its function is the emergency release of excessive water pressure. A perpendicularly placed breather has a name - safety or stall.

Check valve design

How the valve works

The water seal performs the protective function of the water supply system from critical pressure parameters in the pipeline or water heating equipment.

The main reason for critical situations is the interruption of water supply in the main line, excessive pressure or overheating of electric titanium. In these cases, a water lock prevents the outflow of water from the boiler back into the pipeline or vice versa relieves excess pressure.

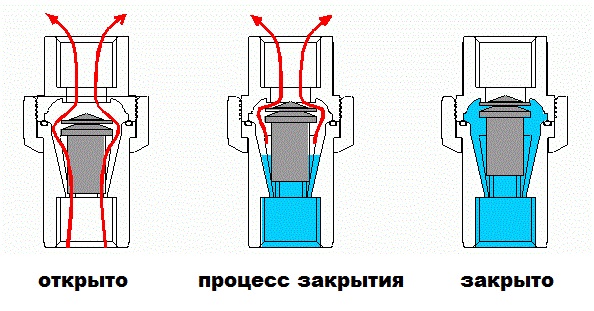

The principle of operation of the valve is quite simple and consists of the following steps:

- the incoming water flow into the device under a different pressure level affects the locking element (plate) and wring out the spring, which kept the throttle closed;

- after compression of the spring, the pressure follows through the opened window further in the required direction;

- if the pressure in the system drops, the spring closes the check valve and the water from the boiler does not go back into the water supply.

In such a simple way, the titanium remains full and does not overheat, as many users leave the boiler plugged into the power network around the clock.

The principle of the check valve

Where and how to put a non-return valve on a water heater

A non-return valve can be supplied with the boiler. But it depends on the manufacturer. Companies with a popular name consider it the right decision to provide the consumer with the necessary installation kit, up to valves.

If titanium is supplied without a water seal or there is a need to change it, you should buy the device yourself. Its cost is small and ranges from 250 to 400 rubles.

The threaded part of the connection does not create questions. Most hydraulic valves are designed for ½ inch thread pitch. But the pressure can vary significantly. In order to find out the necessary parameter, it is worth looking into the manual for the boiler.

If you buy a water seal with characteristics for less pressure, it will drip regularly with different intensities. In the event that the water damper, on the contrary, is of greater importance, then when the boiler overheats, it will not work. This may cause damage or leakage of the housing.

Check valve mounting location on the boiler

Replacing the safety valve on the water heater

Before installing the water seal, it is necessary to disconnect the heater and drain the water from it. To work, you will need:

- check valve;

- Adjustable wrench (2pcs);

- fum tape / tow;

- dry rags.

The process is quite simple. It should shut off the water. Then, it is necessary to hold the water damper body with one key and disconnect the hose from the inlet with the second. After disconnecting the hose, unscrew the device from the boiler. Clean the threaded connection of the titanium inlet pipe from the old tow or fum tape.

Apply a few new turns of fum tape or tow on the receiving pipe and screw in a new water seal. Then do not stretch the connection with the adjustable wrench. After that, put a couple of layers of fum tape or tow on the fitting “dad” of the check valve. Then screw in the connecting nut of the water supply hose. Open the valves of the valves and check the connections for leaks. Everything, installation is completed.

If water will be added from the drainage hole, one should not worry, as this is normal. The non-return valve works and performs its direct function. You can put a thin transparent hose on the branch and direct it to the drainage or sewer.

Some heater owners are trying to hide the check valve out of sight. In pursuit of their goal, they can put it at a considerable distance from the boiler. The scheme of remote placement of a hydraulic lock is not prohibited, but in this case it is impossible to install locking units or taps in this interval. In addition, a long vertical line can create additional pressure, which will lead to regular idling.

The permissible distance between titanium and the water seal should not be more than two meters. Exceeding the regulated distance entails the ineffective operation of the protective device.

In the event of a regular pressure drop in the water supply, it is recommended that a water pressure gear be installed in front of the non-return valve.

How to open the safety valve for a water heater

Normal or slightly increased pressure in the pipeline will not be able to squeeze the spring of the safety "stall" throttle. To open it, a serious gain is needed. There is a drainage tap behind the nozzle plate. Excessive water pressure will come from here.

The perpendicular valve body may be designed with a blank end. A screw plug is sometimes used as a cover. If you remove it, you will have access to the screw for the internal hexagon. But hydraulic locks with a lever and a screw for a screwdriver are more popular.

Safety valve

The vertical position of the lever keeps the safety valve throttle closed. If you lift it up and put it in a horizontal state, then the “stall” throttle will open and the water will be discharged through the drainage outlet.On the branch there may be embossed faces or flaring at the end for anti-skid. This is necessary to use a thin hose to drain water into the sewer.

Sometimes a small tap is used to drain the water from the boiler. This is necessary during dismantling, preventive or repair maintenance of the water heater, if there is no special fitting for draining.

All hydraulic locks are marked in the form of an arrow on the body. This is information about the direction of water flow during installation. In addition, limit pressure information for triggering the stall valve may be provided. These can be the numbers 0.7 MPa or 7 atmospheres.

Do not neglect the technical regulations when installing the water seal on the heater yourself. The desire to save on the installation of a check valve can lead to an unpleasant situation.