Every year, changes occur in our lives. But despite the progress, hot water supply in high-rise buildings often occurs intermittently. In addition, the quality of the coolant itself does not always meet the standards. Therefore, many practical people have long ago installed their own water heaters in apartments. They provide hot water to all residents of the apartment in the right amount. Therefore, it is necessary to choose the right equipment.

There are many recommendations for choosing this electrical equipment. The main parameter of choice is its technical characteristics: power, performance, functional features. But besides this, you should pay attention to the material from which the inside of the tank is made.

How to choose the inside cover of the tank

The inside of the water tank - which is better?

Today, manufacturers offer water heaters with 3 types of internal anti-corrosion coating:

- titanium coated;

- from stainless steel;

- made of glass porcelain.

They reliably protect the tank from corrosion processes. In other words, the duration of operation of the device depends on the inner coating of the tank.

Which tank is better to choose a water heater with? These questions are often asked by buyers. It is impossible to unequivocally answer this question. After all, each of them has its pros and cons.

Enamel and glass ceramics: advantages and disadvantages

Today, customers give preference to glass-porcelain-coated water heaters. Such equipment is characterized by a minimum price compared to others. So, the advantages of these units:

- Profitable price.

- Preventive work to eliminate pollution (sediment) on the coating of enamel is easy to eliminate. To do this, just use a good detergent.

- Enamel is an inert material that exhibits resistance to various chemicals. For example, only aggressive compounds such as hydrofluoric acid can damage the glass ceramic structure.

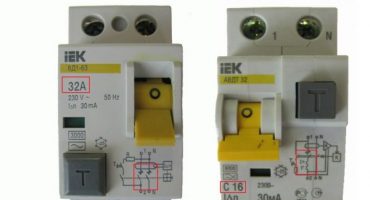

Boiler with enameled tank and magnesium anode

The disadvantages of such an internal coating of the tank include:

- The equipment is faced with the problem of good adhesion between the coating and the metal of the tank.

- Ceramic coating differs significantly in the composition of the metal of which it is made boiler. Often, due to constant temperature changes, the materials are delaminated from each other. But the use of glass ceramics in the manufacture of equipment virtually eliminates this drawback.

- The composition of bulk enamel may include coloring pigments. The latter often contain arsenic and lead - substances harmful to the body. But it should be remembered that devices manufactured over the past 20 years with a glass ceramic tank do not have such a drawback.

- Ceramics is a rather fragile material. Abrupt shaking can cause damage to the coating. But this indicator is not important for mounted water heaters permanently.

Interesting! Enamel and glass porcelain are particularly sensitive to temperature extremes. Often this causes microcracks to form on the surface.

To avoid this, some users use the equipment, setting the maximum temperature of water heating on it to 600C. But experienced specialists recommend increasing the temperature of heating water to a maximum of at least 1 time per month to prevent the development of harmful bacteria inside the tank.

The warranty from the manufacturer for enameled water heaters is 1 year.

Stainless steel: advantages and disadvantages

Stainless steel water heaters are classified as expensive equipment. In principle, this affects their duration of operation.

Stainless steel water heater

The advantages of boilers with such a coating include:

- The coating is resistant to various shocks and damage, compared with the above model.

- Such water heaters are not afraid of temperature extremes. If the equipment suddenly overheats due to the lack of fluid in it, then it will not suffer. It will only be necessary to replace the heater and other parts that may fail due to high temperature.

- The life of such boilers is longer than the above models.

- The warranty period for containers with such a coating varies from 7 to 10 years.

The disadvantages include:

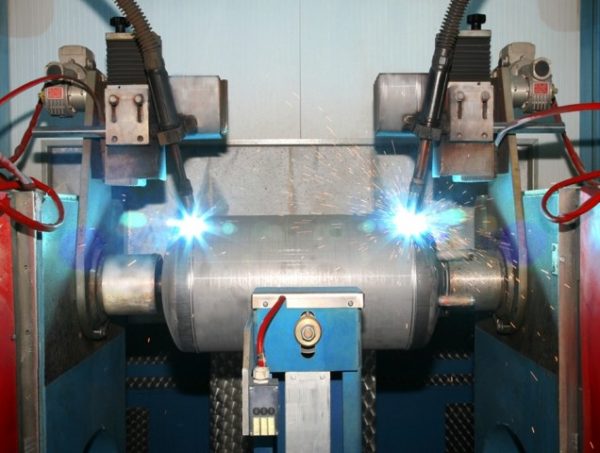

- Stainless steel is corrosion resistant. But if a simple welding method was used, in this place the composition of the metal is different from the main one. The use of outdated technologies in the manufacture of equipment can cause oxidation at the seams. In addition, it should be remembered that all chemical reactions at elevated temperatures occur much faster.

- Many people recall the toxicity of iron, which is in direct contact with water. But a negative effect on human health can only be caused by ferrous iron. Such a connection can hardly be formed upon contact of steel with water. In addition, surveys with ultraprecise instruments and methods did not show the presence of this element in large containers, with the exception that water itself could become its source.

- The price of equipment for heating water with stainless steel coating significantly exceeds the cost of the above models.

Plasma welding is used in the manufacture of a tank for a water heater

Titanium-coated water heaters: advantages and disadvantages

Boilers with internal titanium coating are quite rare. They belong to a small class of devices. This light and chemically resistant metal is electrostatically applied. The result is a high resistance to corrosion processes of the protective layer, increases the strength of the equipment.

Due to the high adhesion and strength of the metal, the water heater can operate at high temperatures. This eliminates the risk of damage or delamination of the protective coating.

The vulnerability of the titanium coating are welded joints. Corrosion often manifests itself in these areas. And the cost of such equipment is quite high.

Two-layer titanium enamel boiler

Glass Porcelain Coated Water Heater Tips

Such water heaters are considered the most common. Unfortunately, not everyone can afford to purchase expensive equipment. But with proper operation, you can achieve uninterrupted operation of the equipment for a long period.

- Models with a magnesium anode should be preferred. Its presence significantly reduces the activity of oxidative processes, which negatively affect the performance of the equipment.

- It is necessary to periodically replace the magnesium anode.

- At the water inlet, a coarse filter must be installed. Sand grains and other particles trapped inside the boiler can damage the surface from the inside when heated.

- Try not to overheat the tank. For domestic needs there is enough water, a temperature of 50-600FROM.

Routine inspections and cleaning will extend the life of your device

- 2 times a year to be carried out water heater cleaning. This procedure will significantly extend the life of your device. At the same time, plaque is removed from the walls and bottom of the tank, TEN is descaled, the deterioration of the magnesium anode is checked, and then replaced if necessary.

In stores today there are various devices for heating water. They differ from each other not only in functionality, but also in the internal coating of the tank: stainless steel, glass ceramics, titanium coating. Each of them has its advantages and disadvantages. But despite the selected model, it should be remembered that proper care is the key to long-term operation of the device.