A self-made dryer for vegetables and fruits from standard purchased parts will be no worse than industrial.

Homemade drying chamber

Before starting to make a dryer for vegetables and fruits, read the main requirements for drying. You can dry any fruits, vegetables and fruits in which moisture is present:

- berries;

- mushrooms;

- apples

- fish.

The drying principle is simple and well-known. Under the influence of temperature, moisture is removed from apples, vegetables, berries and fruits. Therefore, a constant temperature of 50 to 60 ° C should be maintained in the dryer body while removing moisture. For juicy fruits, one hour drying is provided at a temperature of 60 ° C and subsequent hours from 50 to 55 ° C. How to make an electric dryer will be discussed in this article.

What are the designs of dryers

There can be many reasons for making do-it-yourself dryers of different sizes and capacities for fruits and vegetables: productivity is not satisfied, high price, high energy consumption, and others

There are three options for making DIY dryers for vegetables, fish or fruits:

- electric;

- on wood;

- sunny.

Other options for making homemade products, such as sublimation, UHF, infrared, using a vacuum, we will not consider because of the difficulty in manufacturing.

Of the three above options, only electric can work in automatic mode.

On wood and solar, they require the presence of a person and adjustment can be carried out only with slide gate valves to regulate the flow and removal of air.

Let us consider the manufacture of a dryer with a capacity of 50 to 100 kg of raw weight of the product at home, based on the fact that a home craftsman plans to sell some of the dried products.

Energy intensity

A factory dryer with automatic equipment for processing dried apricots consumes about 1.6 kWh of electricity per 5 kg of crude product and dries 36 hours.

Based on the averaged data, the jack of all trades should take into account that a home-made dryer for processing 50 kilograms of raw apricot-type product will consume 16 kW of electricity, and for 100 kg 32 kW. Using simple mathematical operations, you can find out the future costs of cooking 1 kilogram of fruit.

For household consumers, a maximum power consumption of 3 kW / h is provided. Accordingly, it is possible to select 16 kW from the line in 3 hours, and 32 kW in 6 hours of continuous operation. But in 3 or 6 hours to dry foods with a high water content will not work.

Conclusions: in a domestic environment, building a dryer with a capacity of more than 50 kg of dry product is not problematic if there is no restriction in electricity consumption. Accordingly, if someone decides to build a dryer for 100 kg, then he will have to increase the drying time by 1.5 times. And then 100 kilograms of crude product will have to be dried for 3-4 days with an increase in electricity consumption up to 32 kW.

Do-it-yourself electric dryer of fruits and vegetables

To do this, you need to make the body of an electric dryer, buy a fan, a heater, a temperature sensor (thermostat), a timer, two chimney draft regulators.

Tips: Before you start building a dryer with a power consumption of more than 3 kW, ask your local energy company about the maximum power that they can provide you.

Fan

For our purposes, household smoke exhausters for boilers are best suited.

Smoke exhausters for domestic boilers

Their distinctive feature is that they can pass air through them with temperatures up to 150 ° C without damage to the electric motor. An ordinary axial fan is not suitable for these purposes. He is not able to work at a temperature of 50 ° C for a long time. The diameter of smoke exhausters starts from 150 mm. An electric spiral heater with an open spiral must be placed in the pipe going from the smoke exhaust.

Tips: you can buy a fan for boilers of the "snail" type with a capacity of at least 50 times the volume of the drying chamber.

Electric heater for dryer

For maximum heat removal, the heater must be with an open spiral. The power is calculated from the calculation of the permissible rated power for the house and equals 3 kW minus the power of the exhaust fan and household appliances. If this norm is exceeded, then the automation will operate and turn off the light in the house.

Open coil electric heater

When choosing an electric heater, consider its dimensions. It should fit in a pipe that connects to a smoke exhauster or fan that supplies air to the drying chamber.

Smooth thermostat

Temperature regulators with stepless temperature control from 0 to 300 ° С are a standard part of all domestic electric furnaces. It must be connected in series with the electric circuit with electric heating elements and a fan. Upon reaching the required temperature, it will automatically turn off the heating and fan.

Household thermostat

You can use a thermocouple from ovens.

Where to buy a thermostat? There are several purchase options:

- online store;

- The nearest workshop for the repair of household appliances.

It is possible to purchase a thermostat in a flea market.

Time relay

In order to fully automate a home-made dryer, you need to buy an electronic two-channel time relay with programming for a week.

There are many options for the execution and programming of the time relay and everyone will be able to choose the right one for themselves.

By connecting a fan and a heater to the time relay, you can configure it to work empirically. To do this, you need to set the turn-on time of the heater and fan.

Chimney draft regulator

Draft regulators are installed in stainless steel chimneys. This automatic device is a precisely fitted valve on the axis. In order for it to be always closed or open on one side, a small load is installed.

Install these two valves in the inlet and outlet openings of the dryer. When the fan is off, they will close the inlet and outlet of warm air under the weight of the load.

Traction control

The use of these valves will automate the intake and supply of air without the use of actuators and expensive command controllers.

For especially advanced jacks of all trades, we recommend buying a programmable command controller. This equipment is more complicated, but it allows you to automate all drying processes, connecting humidity, temperature sensors, motors, slide gate valves and other actuators. They are widely used for drying lumber chambers.

Some practical advice

When building a drying compartment, use the following materials for the frame:

- wooden slats;

- chipboard;

- wood-fiber boards;

- oriented particle boards;

To heat the drying chamber, use:

- polystyrene foam boards;

- mineral wool;

Take into account that the insulation is installed outside, not inside!

Homemade drying chamber

To fix the insulation, use:

- Titanium glue, mounting foam for polystyrene foam boards:

- plastic fungi for mineral wool.

Cover the insulation with a fiberboard plate or seal with aluminum self-adhesive foil. In extreme cases, it can be plastered with plaster on a synthetic mesh. It is sold in construction stores for insulation of houses.

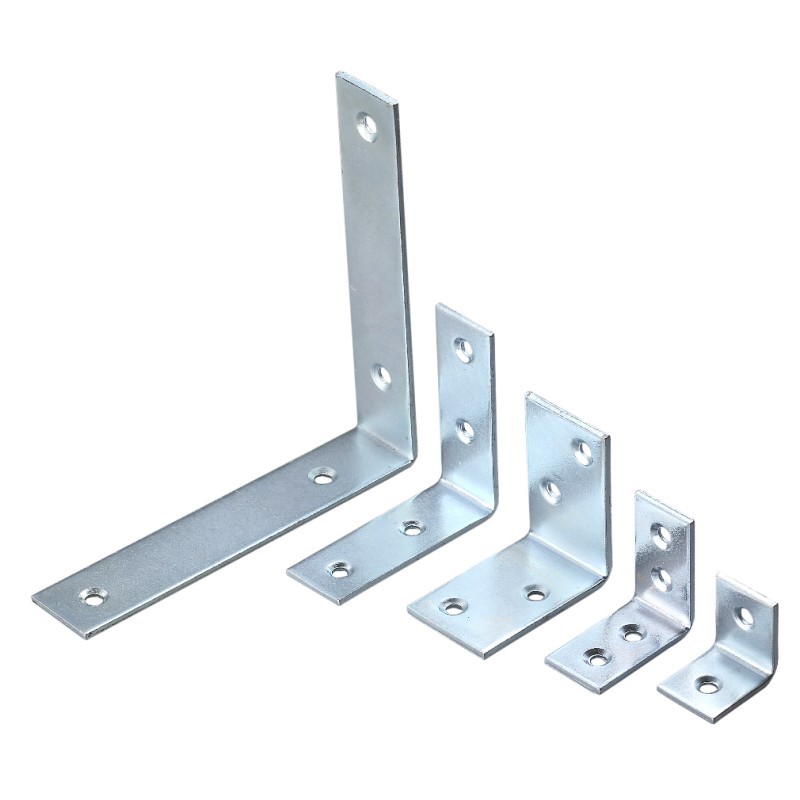

If there is no necessary woodworking equipment to stiffen the frame, use metal corners for window frames.

Metal corners

It is better to connect a wooden frame with screws than nails.

Please note: for the calculation of the cross-section of wires, there is such a rule: 1 mm requires 0.7 mm2 wire cross-sectional area. Thus, for a drying chamber with a rated power of 3 kW, the cross-section of the wires should be at least 2.5 mm2.

Dried fruits

For safe operation, the metal parts of the dryer must be grounded.

When calculating the volume of the dryer, design a load on 1 pallet of not more than 5 kg of wet product. If you put pallets with an interval of 10 cm, then the height of the chamber with 20 pallets will be 2 meters. In this case, a problem with loading to a high height may occur.

To combat mold and other diseases that occur in a humid and warm atmosphere, use an ultraviolet lamp.