The ability of metal parts to heat in an alternating magnetic field has been used in everyday life for more than 40 years. Appliances installed in the kitchen for cooking have a modern design, high-quality ceramic coating and high efficiency due to the direct heating of metal utensils.

Induction hotplate

Despite the significant advantages of induction heating devices over conventional electric stoves, repair of such products can not always be done on their own.

Sophisticated microprocessor control of induction, installed in such devices, requires a sufficiently high qualification of the master, repairing this household appliance. The absence of direct heating of the element emitting a magnetic field almost completely eliminates the possibility of occurrence of malfunctions of the "burned out conductor" type. Therefore, if there are any serious deviations in the operation of this device, or the device does not turn on at all, then if you wish to repair this device yourself, you will need:

- minimum knowledge in the field of electronics;

- diagnostic devices, soldering iron and soldering materials;

- the presence of a large amount of free time;

- moral readiness for the fact that after an attempt to repair such a complex device as an induction cooker on its own, the device can be completely damaged.

If you have everything you need, the first thing to do is to identify the main causes of the malfunction of modern induction cookers.

Induction stove does not work - causes and do-it-yourself repairs

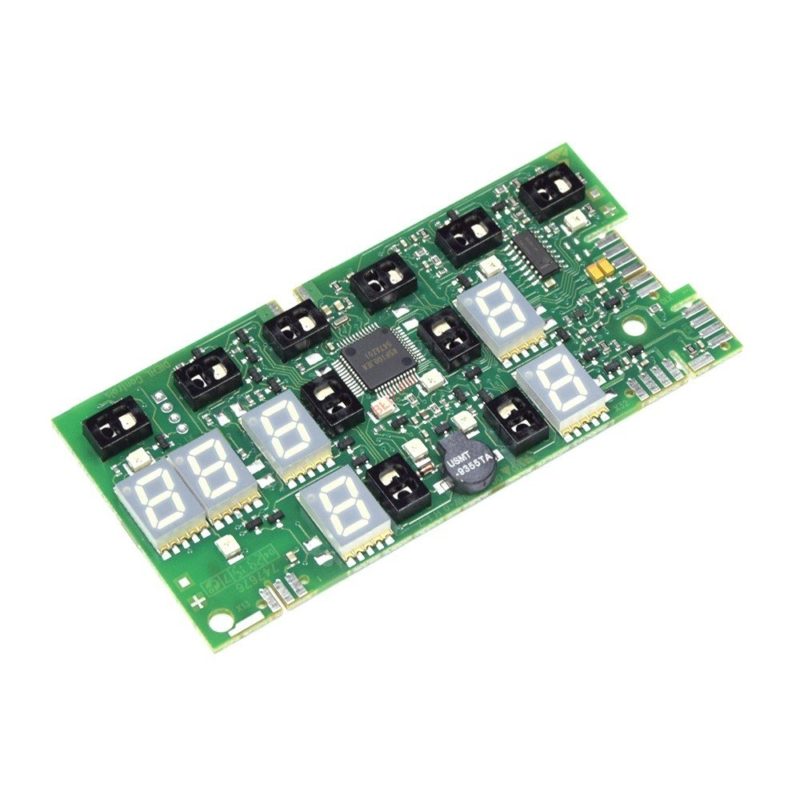

Control block

Unlike a conventional electric stove, there is a control unit inside the induction appliance, which often fails due to liquid entering the housing.

Of course, the cause of a device breakdown is not always a short circuit, but before starting repair work, it is necessary not only to perform certain diagnostic steps, but also have a detailed "history".

If the induction cooker refused to work without any apparent reason, then you should be aware of the most common breakdowns of this type of equipment. The inoperability of the induction cooker can be caused by:

- improper use of a household appliance;

- factory marriage;

- short circuit as a result of liquid entering the device case.

If the induction cooker was operated correctly and a malfunction occurred during the warranty period, then the most correct solution in this case would be to contact a service center to carry out warranty repairs. In all other situations, you can try your hand at repairing complex household appliances. Next, the most common breakdowns of household induction stoves will be sorted.

Insufficient power

If the induction cooker does not give out rated power during operation, the device itself is not always the reason for this. Very often, a decrease in the power of a given electrical device may be due to:

- mismatch of the voltage supplied to the home electrical network;

- using the wrong utensils;

- inclusion of electronic protection as a result of overheating of the winding.

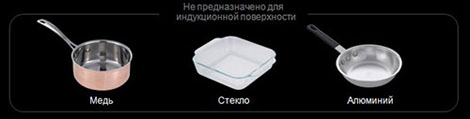

Unsuitable cookware

With significant voltage deviations in the 220 V network, the induction cooker can not only work unstably, but also completely fail. If it is known that the magnitude of the voltage is often unstable in a given area, it is recommended for induction hobs install the stabilizer. When installing a voltage stabilizer, you should choose a model whose power should exceed the rated power of the plate by at least 10%.

The use of utensils whose bottom diameter significantly exceeds the manufacturer's recommended values can also lead to unstable operation of the household appliance. Too small a pan or pan can also cause a reduction in the power of the device.

Small saucepan

During cooking, it is necessary to monitor the location of the dishes exactly in the center of the cooking surface. If the dishes are shifted relative to the center of the induction field, this will lead not only to a noticeable decrease in power, but also to an increase in the negative impact of magnetic radiation on the human body.

The plate also has built-in protection against overheating of the winding, but a decrease in the power of the device as a result of the operation of such a function is very rare. All induction hobs are equipped with a forced ventilation system that does an excellent job. Overheating of the winding can occur when the plate is not installed on a hard surface. In this case, it is possible that the plate will sink under the weight of the dishes and its own weight, which will necessarily lead to the overlap of the air intake holes in the device body.

Also, the protection can be triggered by a decrease in the fan speed as a result of winding hair, thread or kapron fishing line onto the motor shaft. If the decline induction cooker power formed for this reason, it is enough to disassemble the device and clean the blades and fan shaft from contamination.

The stove does not turn on

If the power reduction of this device can not always be determined at the time of the malfunction, then in the case when the electric stove does not turn on, the device clearly needs to be examined immediately for critical violations.

Fortunately, situations where the electrician does not start the main element emitting a magnetic field, the element is not always associated with a malfunction of the household appliance itself.

If the dishes are not made of ferromagnetic alloy, then cooking in such kitchen utensils will not work. When using dishes whose bottom diameter is significantly less than the recommended value, the device cannot be turned on either. If cookware is used for cooking, which fully complies with the requirements imposed by the manufacturer of the household appliance, then it will be necessary to conduct complex diagnostics of the device.

Reasons for inoperability of induction cooker:

- The power cord is not fixed.

- Blown fuse.

- The coil control module is not fixed.

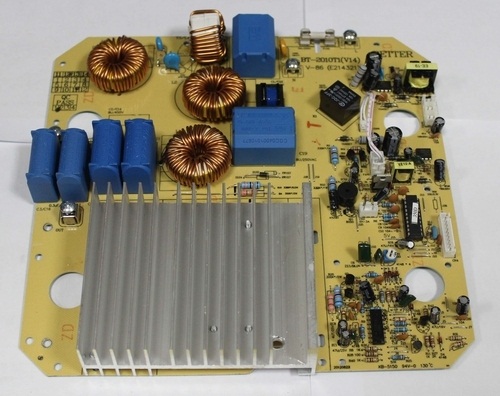

Power block

- The touch control panel has broken.

When the power cord is faulty, the indicator light and any manifestations of the life of the household appliance are completely absent. In this case, it is necessary to disassemble the device and ring the cable from the plug to the terminals on the power filter board with a multimeter.

If a resistance equal to zero is obtained by any of the conductors, then first of all, you should inspect the wire at the place of its entry into the device body. Especially often, an internal breakage of the current-carrying cable core can be observed in this place with portable single-burner models. Such household appliances are much more often moved from place to place, which can lead to mechanical destruction of the copper conductor.

The second most popular place for the destruction of an electric current-supplying device is a plug.This malfunction is especially often manifested in inexpensive plates, in which, for the sake of economy, a conductor of a smaller diameter is used than is necessary.

Both problems associated with the violation of the integrity of the conductor are eliminated quite simply. In the first case, to eliminate the breakdown, it is necessary:

- Disassemble the household appliance.

Disassembled stove

- Trim the wire at the entrance to the household appliance.

- Strip copper conductors.

- Ring the conductor with a multimeter or tester.

Collapsible fork

- Remove the part of the wire remaining in the plate body.

- Install the power cord and correctly connect the two main conductors and the ground conductor.

If the cause of the inoperability of the device was caused by a malfunction of the power cord, then after assembly, the device can be used immediately for its intended purpose.

In the event that the malfunction is caused by the burning of the wire in the plug, it must also be cut off and replaced with a collapsible three-pin product.

The induction cooker may not turn on at all because of a fuse failure. To replace the fuse, you will also need to disassemble the household appliance, but the repair process itself will not take much time, and to diagnose such a failure, it is enough to ring the part with a multimeter or tester.

If during the implementation of diagnostic actions an open circuit with a fuse is detected, it is enough to replace this element, then assemble the household appliance, after which it will be possible to use the stove in standard mode.

The plate turns on, but the operating mode does not start

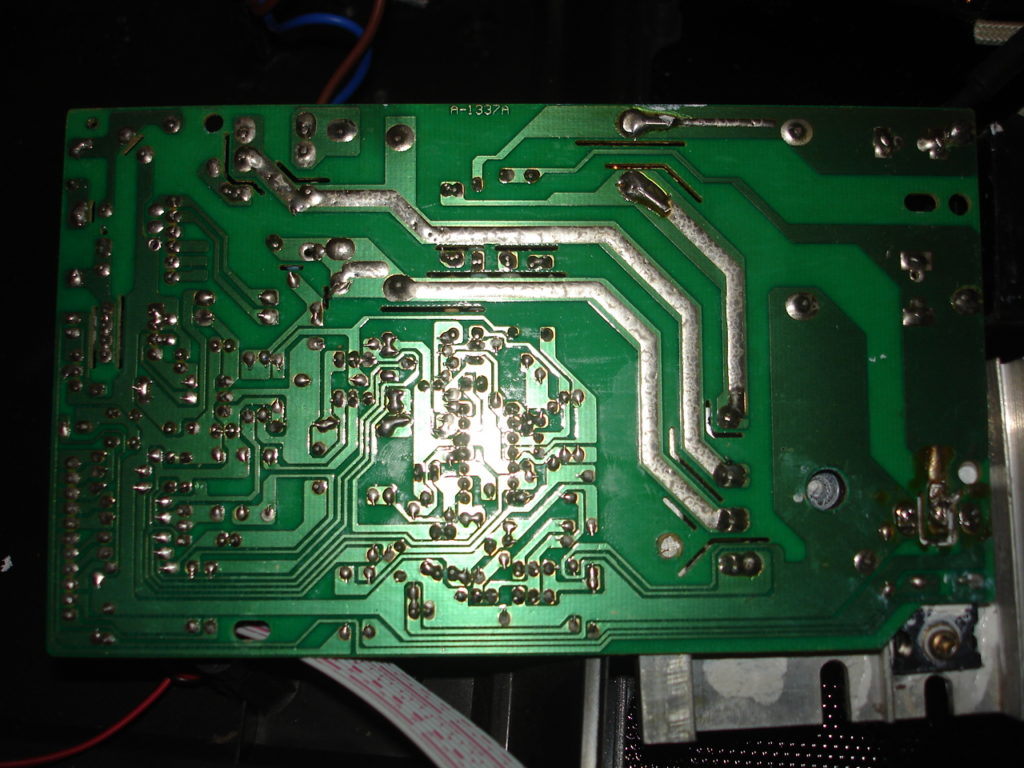

Power module (rear view)

If the control module or touch panel is faulty, then most often the elimination of such a breakdown is carried out by replacing with a known-good board. In low-cost models, the IGBT transistor, which takes part in the conversion of direct electricity to alternating electric current, can fail.

IGBT Transistor

To check the transistor, it is enough to disconnect the power board on which this element is installed, turn it over and ring the part with a multimeter.

Before proceeding with diagnostic actions, it is necessary discharge high voltage capacitorsinstalled in the power board of the device.

In order not to damage the internal contacts of the device, it is recommended to perform this operation using high resistance. After removing the residual electricity, if the transistor is broken, it is enough to purchase a new electronic element and install it instead of the burnt part.

After dismantling the board, in addition to the power transistor, it is imperative to ring the diode bridge, which is made in the form of a four-pin microcircuit. If this part malfunctions, it should also be replaced. After carrying out repair operations, the board is put in place, and previously disconnected wires are installed in the corresponding connectors.

Conclusion

Repairing a modern induction cooker with your own hands can very well be done at home using conventional soldering materials, a soldering iron and a multimeter. Before proceeding with a complicated repair, it is imperative to check the most simple malfunctions that can happen with this household appliance. If it is necessary to solder parts, then this operation should be carried out very carefully. Badly soldered parts can also cause the device to turn off, but diagnosing this malfunction will be much more difficult. In general, if the diagnosis is done correctly, then 90% of cases of device failure can be completely eliminated on their own.