Making useful household items, tools and electrical appliances with your own hands is not always associated with the desire to save. The spirit of invention lives in almost everyone who at least once held a wrench or screwdriver in his hands. For those who are not able to throw a gram of copper wire and even an old unnecessary razor blade into the trash, it will be useful to find out how a workable boiler can be made from such improvised items.

A do-it-yourself boiler can be made in various ways, but not all options for self-assembly of this device allow you to use it for a long time. The article describes the basic, time-tested options for self-manufacturing a boiler.

How to make a do-it-yourself boiler - the best of proven ways

Most often, in artisanal conditions, boilers are made of:

- Razor blades. Blades Sputnik.

- Nails

- TENA for a teapot.

TEN from an old teapot

TEN from an old teapot

You can also make workable appliances for heating water from a nichrome wire, which is installed on a ceramic insulator at home.

The main task that should be carried out with the self-design of heating elements is to minimize the possibility of short circuit and electric shock. When using low-voltage home-made products, electric shock is practically not to be feared, but devices operating from a 220 V network can cause accidents and fire.

Blade boiler

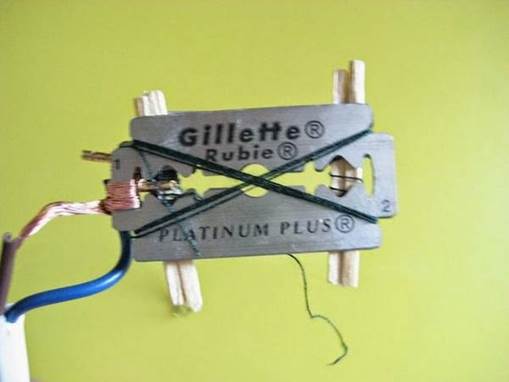

It is not difficult to make a boiler from razor blades. To perform the work, it is necessary to prepare the following components:

- 2 blades of the "Satellite" type.

- 2 matches.

- Two-wire cable with plug.

- Threads.

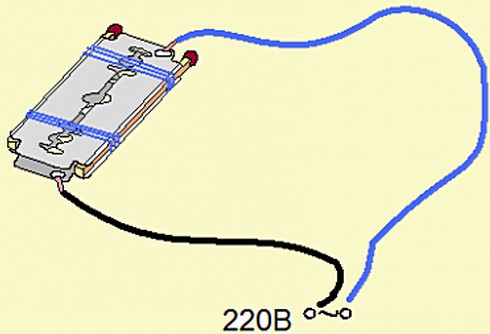

Blade electric boiler circuit

The assembly process of a homemade boiler is as follows:

- A copper core of an electric wire is tied to each blade.

- Between the blades are placed 2 matches, which will serve as spacers to protect against short circuit.

- Blades of thread are wound to matches in such a way as to exclude the free movement of metal parts.

Home-made water heater assembly

Homemade blade boiler is fully ready for use!

Homemade device test

Now it remains only to pick up a tank in which it will be possible to boil water. The container that will be used with a boiler of this design should not be made of conductive material. Extreme care should also be taken when turning the device on and off. Before you turn on a home-made electric device in a 220 V network, you must first lower the device into water. When heating water, it is strictly forbidden to touch an electrical device or a container of water.

In addition to the necessary safety measures, it is also necessary to remember that water heating in this way is possible only if there are conductive metal salts in it. Distilled water from the blade boiler will not heat up, due to the absence of a conductive medium between two metal planes.

In addition, the use of an electrolytic method for heating water negatively affects its taste, therefore this heating option is most suitable for industrial fluids.

Boiler from the heater

To make a boiler at home from a heating element is no more difficult than using razor blades. This version of a home-made device with proper manufacture is safer to use.

TEN is not difficult to “extract” from old kettlewhose malfunction is not related to the heating element.

In addition to the availability of a functioning heater, you will also need to prepare a two-wire wire with a plug, which can also be borrowed from a faulty kettle. Also, for attaching wires to the heater, it is recommended to purchase terminal blocks, the use of which will greatly simplify and accelerate the process of self-manufacturing of the device. In this case, the assembly process is carried out in the following sequence:

- The ends of the wire are cleaned from insulation with a knife or a special device.

- The wires are fed into the terminals and then fixed to the TEN terminals with built-in screws.

- Using a multimeter, the resistance of the heating element is checked, as well as a possible leak on the product body.

Water heater from the heater from the kettle

With successful diagnostics, a home-made device can successfully compete with factory products, and the quality of the connection of the main wire to the heater can even be performed better than that of store-owned household appliances. The absence of soldered joints will allow this device to last much longer, but if there are no terminal blocks, then the above-described embodiment of the boiler can be made by soldering the wires to the contacts of the heating element.

This version of a homemade boiler can be used without any restrictions. The quality of boiled water prepared in this way allows you to brew tea, coffee or any other drinks without loss of taste.

From nails

An electric device made of nails is a variation of a boiler made of blades, but with a more “civilized" design. To make this water-heating device it is necessary to prepare:

- 6 nails 80 mm.

- Two-wire copper wire with plug.

- Electric drill and drill 3 mm.

- A piece of wooden board 100x100 mm, a thickness of at least 25 mm.

Nails for a homemade hot water device

The process of making a boiler of nails is carried out in the following sequence:

- In the middle of the wooden plate, 6 holes with a diameter of 3 mm are made with a distance between them of 3-5 mm.

- A steel nail is installed in each hole in the wood plate.

- From the cable with the plug, each contact is connected to 3 nails.

- A wooden plate is mounted above the tank and is connected to a 220 volt network.

In carrying out these actions, it is necessary to strictly monitor that the wires are pressed as tightly as possible to the metal surface of the nails. To ensure reliable contact of the wires with the electrodes, it is recommended to insert 1/3 of the copper core of the wire into each hole before installing the nails in a wooden plate. If all the steps were done correctly, then when checking the resistance between the contacts of the plug, the multimeter should show a zero value.

Use this device for heating water should be in the following sequence:

- Pour water into a non-metallic mug, which should not be distilled.

- Place the wooden plate on the mug with the electrodes down.

- Connect the device to 220 V.

- After boiling the liquid, the home-made boiler should be disconnected from electricity.

As in the case of using a product from razor blades, the quality of the boiled liquid leaves much to be desired, therefore this method of preparing boiling water is also better used for technical needs.

The most powerful home-made boiler

Nichrome spiral

In order to boil a large volume of water, you can make a powerful portable device from improvised means. For the manufacture of the device you will need the following details:

- Nichrome spiral with a wire diameter of at least 1 mm.

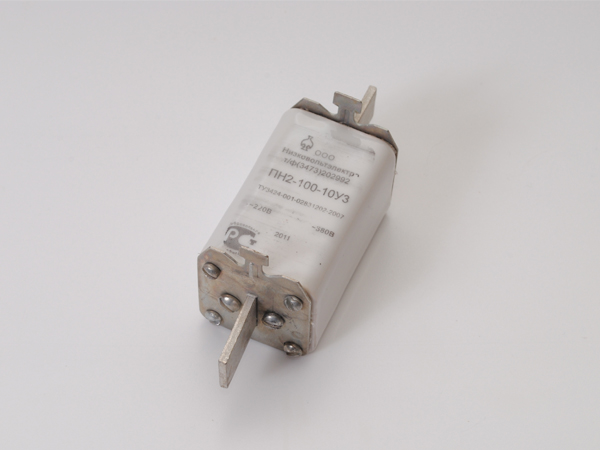

- Industrial fuse PN 2 series.

- Two-core cable from a wire with a cross section of at least 4 mm2.

- Screwdriver and wood screws 20 mm.

- Collapsible plug.

Fuse PN-2

The manufacture of a powerful device for heating water is carried out in this sequence.

- The PN-2 fuse is disassembled to remove the ceramic body of the product.

- 8 screws that were formed during disassembly of the device are screwed into the holes in the body of the ceramic insulator.

- The end of a nichrome spiral clings to one of 8 screw-in screws.

- Then, inside the body of the electrical insulator, the spiral is pushed to the opposite end of the circular insulator and is again fixed around the screw.

- The spiral turns in the opposite direction, but is already fixed to another screw screwed into the insulator.

- In the same way, the spiral and self-tapping screws are connected at another 5 points, after which the stripped copper wires are connected to the first self-tapping screw and the last and the self-tapping screws are completely screwed into the ceramic insulator. Given the significant power of such a home-made boiler, the cross-section of the connected copper wire should be at least 4 mm2. On the other end of the wire is the installation of the plug.

Checking a powerful home-made water heater

Operation of the boiler can only be carried out in limbo. The heating element must be completely lowered into the water and should not touch the walls and bottom of the tank. When using homemade powerful boiler It is strictly forbidden to touch the container and the body of the device while heating the water.

Conclusion

A boiler from improvised means can be made with your own hands without financial costs. Without exception, all home-made products should be operated in such a way that the human body does not come into contact with a heated fluid or with an uninsulated part of live parts. It is forbidden to leave the boiler made by yourself without supervision, as well as in places where children can be accessed to the switched on device.