Refrigerator operation directly related to the circulation of freon in the system. This process is provided by a specialized unit - a motor-compressor. If the performance of this unit is lost, or if the compressor does not start (or starts and immediately turns off) on the refrigerator, the refrigerator will not be able to perform its direct function - cooling.

Refrigerator compressor

However, the node does not always start due to a malfunction. In fact, there may not be a breakdown at all, but the motor will not start due to insufficient voltage. Also, the reasons may be related to the breakdown of other nodes. For example, wiring or failure of the stabilizer. In this case, the refrigerator will be de-energized, respectively, will not start. If the relay clicks, but the engine does not start, there is probably a short circuit in the windings of the appliance, and the start relay itself may also malfunction.

Compressor Symptoms

If the refrigerator works with temperature violations, often turns on or, on the contrary, almost does not turn off, it freezes very much - this is an occasion to think about the health of the unit.

Typically, the refrigerator compressor does not start after abnormal operation or overload. Jamming of the unit occurs if you disconnect the device for less than a minute. For this reason, we strongly do not recommend doing this.

You need to check the nodes and look for the reasons in sequence. If the motor works without turning off, the diagnostic area narrows, but this does not mean that a malfunction is necessary in this node. But, even if the reason, for example, is in the control sensors or relays, the refrigerant leak, the situation cannot be ignored. In any case, working for wear, this unit will sooner or later overheat and fail.

Filling the refrigerator with freon

You can talk about the breakdown of the compressor itself if the following symptoms appear:

- The motor is buzzing, trying to start, but this does not happen.

- An oily puddle appeared on the floor under the device.

- The motor is very hot, knocks, vibrates, makes noise at the start and at work.

Since the unit consists of two devices: the engine and the compressor, their breakdowns should be distinguished. In general, malfunctions of the motor-compressor can be associated with:

- interturn and short circuit of the stator windings (applies to the engine);

- winding circuit to the housing (also applies to the motor);

- loss of performance;

- depressurization.

It is possible to determine what exactly happened by indirect signs. If the device works without shutdowns, and the temperature in the cells is high, it is possible that the refrigerant is leaking. Sometimes the diagnosis shows that the compression has disappeared. This indicates the development of the device. It is better to replace it with a new unit.

If the compressor buzzes when turned on and does not start, while there are no short circuits in the windings, it is most likely that a jam has occurred.

The compressor has broken in the refrigerator - what to do

Replacing a compressor is one of the most complex and expensive services in service centers. In addition, the spare part itself is expensive. The experience of the masters and many years of observation show that if a device is worn out, there is a large output, it is better to immediately replace it with a new one. But in some cases, for example, if gaskets, rings or individual parts of the engine are worn, the part can be repaired.The final decision is made by the master, based on the appropriateness of the procedure.

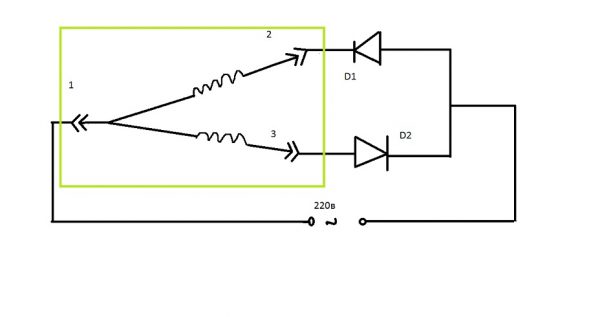

Diode KD 203A

A stuck compressor can try to wedge. For this, a specialized device is used, consisting of 2 diodes with a permissible reverse voltage of at least 400V and a limiting forward current of 10 amperes. For example, KD 203 A, D 232 A, D 246-247.

To eliminate the wedge using this design, voltage is applied to the motor windings for 3-5 seconds. The action is repeated after 30 seconds. You can connect the device through the connectors of the starting relays P1, P2 or P3 or using insulated terminals. The principle of operation of the design is based on the useful torque that occurs on the motor shaft when current flows through the diodes. The rotor of the motor begins to vibrate, the vibration is transmitted to the jammed nodes and releases them.

Electrical schematic diagram of a compressor wedging device

Can I check and repair the compressor myself?

The compressor replacement technology is unsafe, very complex and requires the use of specialized tools:

- oxygen propane burner;

- pipe cutter;

- leak detector (determine with its help also a place freon leaks);

- electronic type thermometer;

- valves for the selection of freon and piercing;

- Hansen couplings;

- dehumidifier;

- pinch mites;

- solder and flux;

- charging cylinder;

- new motor compressor.

You should consider whether it is advisable to purchase all this in order to replace the compressor? Buying all the parts will cost more than the services of a repairman.

Another argument against it is the high danger of work. After all, work is carried out with gas, an explosive substance. Should I put myself at risk? Without experience and the necessary knowledge, there is a risk of damaging the tubes, releasing all the gas or upsetting the balance.

For those who nevertheless decided to do the work on their own or are just interested in how complicated and how the procedure is going, we will describe the technology of work when replacing a motor compressor.

Important! We strongly do not recommend replacing the compressor yourself! It is life threatening!

Dismantling the old compressor:

- Cut with a file and break off the filling tube.

- Notch and break off the capillary tube at a distance of about 2-3 cm from the filter drier.

- At a distance of 1–2 cm from the tube-compressor seam, cut off the suction and discharge tubes, do the same at a distance of 1–1.5 cm from the seam of the condenser-filter with a desiccant. To do this, use a pipe cutter.

- Remove the start relay.

- Remove compressor mount.

- Remove the compressor itself.

- To clean the pipeline.

Compressor removal

Compressor mounting

Installation of a new compressor:

- Install the compressor in the seat.

- Remove plugs from nozzles. This should be done no earlier than a few minutes before soldering.

- Make sure that there is no excessive pressure. This will tell the noise of the outgoing air that you hear when removing the plugs.

- Dock with the compressor nozzles of the tube: those that were cut off at the last stage. The filling tube should have a diameter of 0.6 cm and a length of 6 cm.

- Solder in strict order: first fill, then suction, and then discharge. It is forbidden to direct the burner flame into the motor pipe.

- Remove plugs from the filter drier, install a filter on the conder of the filter and integrate a capillary tube into it. Solder the seams of the entire filter.

- Fit the valve coupling half onto the filling tube.

- Make sure to solder all joints. There should be no unsoldered voids, the seams themselves should be smooth and even.

- Fill the system with freon.

- Install the start relay to the compressor.

- Connect the refrigerator and let it work for several minutes.

- After that, check with a leak detector for a leak.