Modern man cannot imagine life without washing machines. The equipment is expensive, so any troubles with a home assistant cause justifiable concern. One of these common problems is increased vibration, knocking during the spin cycle. In some cases, even leakage may occur. Many consider this problem to be frivolous: they hold the SMA body during the spin cycle, letting the problem go by its own accord. Doing this categorically is not recommended: increased vibration leads to premature wear of parts, and can also be a symptom of an SMA failure. In this article, we will talk about why the machine starts to jump strongly during the spin phase and what, in fact, to do to fix the problem.

Note that vibration cannot be completely eliminated. The most expensive CMA models of recent years of production are capable of wringing at speeds of 1400 rpm and higher. Naturally, at such high speeds, the machine will shake. Therefore, the higher the class spin washing machines, the stronger the device will vibrate.

But most often a narrow AIA jumps, which is also quite understandable. There are several types of washers on the modern market: narrow, super-heavy, full-size, front-loading and vertical-loading machines. Compact SMAs have certain advantages. First of all, it is the ability to install in tight spaces, lower cost. But the technique of this type with the same width and height has a shallower depth (almost twice). In simple terms, full-sized SMAs are in the shape of a square, and narrow in the shape of a rectangle. The support area of narrow washers is smaller, their stability is less. In addition, in compact washing machines, clothes often go astray and an imbalance occurs.

Narrow washer

Full size washer

Vertical washing machine

Take note! Take particular responsibility for installing narrow washers. For reliability, place rubber pads, rugs under the legs, and use other attributes to level the vibrations.

Why does the washing machine jump too much during the spin cycle?

There are many reasons for the jumps in SMA. Some are associated with improper installation and operation, others indicate malfunctions and can occur both due to factory defects and due to the natural wear of parts and components of the washing machine.

So, vibration occurs due to:

- improper installation;

- drum imbalance;

- if you forgot to remove the transport bolts;

- hit between the tank and the drum of the AGR of the seeds of bras, coins, buttons, pins, jewelry, etc .;

- scattering of bearings;

- breakdown of springs and dampers;

- malfunctions of the balances;

- engine breakdowns.

We proceed to a detailed consideration of the issue. From simple to complex.

Transport bolts on a typewriter

Did you just get an SMA, did you get a lot of shaking during the first wash? Check the transport bolts first. These protective bolts are installed to secure the tank, ensuring safe transportation of equipment. If they are not removed, the main parts will quickly fail, the equipment is very noisy and staggering.Bolts are located on the rear panel of the SMA: 2 on top and 2 on the bottom.

Do not forget to remove the transport bolts of the washing machine

Important! Do not discard the transport bolts. They will be useful to you if in the future you need to transport equipment to another place.

Erroneous installation

This is the most common reason why the washing machine starts to jump during the spin cycle. Try to swing the AGR in the off state - if it is free to move, the equipment is unstable. It is for this reason that she begins to shake. Also check how even the SMA is on the surface using the level.

If you have a wooden floor - regularly check the stability of the washer. Such a floor sags over time, and accordingly, even perfectly exposed equipment needs to be adjusted over time.

To give stability to the SMA, tighten the front legs, before aligning the floor on which the equipment is installed. If your model does not provide for adjustment or the legs rot over time (sometimes it happens) - place a piece of cardboard or rubber under the leg.

Do not forget to check! The washing machine must not be installed on slippery or uneven floors. Therefore, before installing the SMA, level the floor, put special supports, a fiberboard or chipboard sheet. Such a backing is especially needed if your floor is wooden.

Imbalance

Sometimes the cause of all problems lies in the banal non-compliance and neglect of the operating conditions recommended by the manufacturer. For some very economical housewives, the washing machine jumps so hard during spinning that you have to hold it with your hands, and sometimes sit on top, since it also shifts. And all the fault is the overload of the AGR.

Do not overload the drum. If the weight of the laundry is above the maximum allowable value, an imbalance occurs, which causes premature wear of the suspension and bearings. Follow the basic rules when downloading:

- Load wool and thin light fabrics onto ¼ of the drum;

- Gentle synthetic fabrics load on ½ drum;

- When fully loaded, leave some space between the things and the top of the drum about the size of a palm. Remember that the maximum load indicator (in kg) is indicated by the manufacturer for cotton items.

In addition, the laundry may get lumpy during washing. For example, if you wash pillowcases and a duvet cover at the same time, the pillowcases can get in the duvet cover.

In modern CMA models, there is protection against imbalance - the function of automatic drum balancing or stopping the mode with highlighting the corresponding error code (UE or UB - read the decoding of fault codes for your model of equipment in the manufacturer's instructions).

How to eliminate the imbalance?

- Unplug the equipment by pulling the cord from the outlet.

- Wait a couple of minutes until the door unlocks - you will hear a characteristic click.

- Open the drum.

- If the door cannot be opened, drain the water from the tank through the drain filter.

- Take things out of the tank and straighten them; if the machine is overloaded, divide them into several parts. Almost all SMA models have a separate spin mode, so there will be no problems.

- After that, load some of the things and close the hatch.

- Plug in the machine - the program should resume. If this does not happen, just start the wash in the spin cycle.

Foreign objects

It so happens that foreign objects fly into the gap between the CMA drum and the tank (especially when spinning at too high speeds). And because of this, there is a strong vibration of the washing machine, a rattle is heard. As in the previous case, the fault is the violation of the operating conditions. In order to avoid a problem, do not load underwire bras into the washing machine in the future, always check your clothing pockets before washing.

Well, if the trouble has already happened - we will understand!

To check the equipment for the presence of extra "spare parts" in the drum-tank space, bend the cuff of the hatch, armed with a flashlight, scroll the drum and carefully examine the space. If you can’t immediately find the problem, will have to remove the heating element of the washing machine and take out the bones through the hole formed. Note that because of the scum it is not always possible to immediately remove the heater. Therefore, without knowledge and experience, it is better not to go into the design of the AGR and entrust this work to a specialized specialist.

Bend the cuff of the hatch and check for foreign objects

Serious problems

If during the execution of a particular washing mode the washing machine not only jumps, but also makes extraneous, uncharacteristic sounds, makes noise during the spin cycle, the reason is a malfunction. Additional symptoms will tell about the presence of certain breakdowns.

So, if the springs or shock absorbers break, then, in addition to vibrations, you will hear the drum knocking on the body of the washing machine. A characteristic knock is heard when the counterweight is weakened. Bearing wear is indicated by shaking and grinding.

How to check bearings

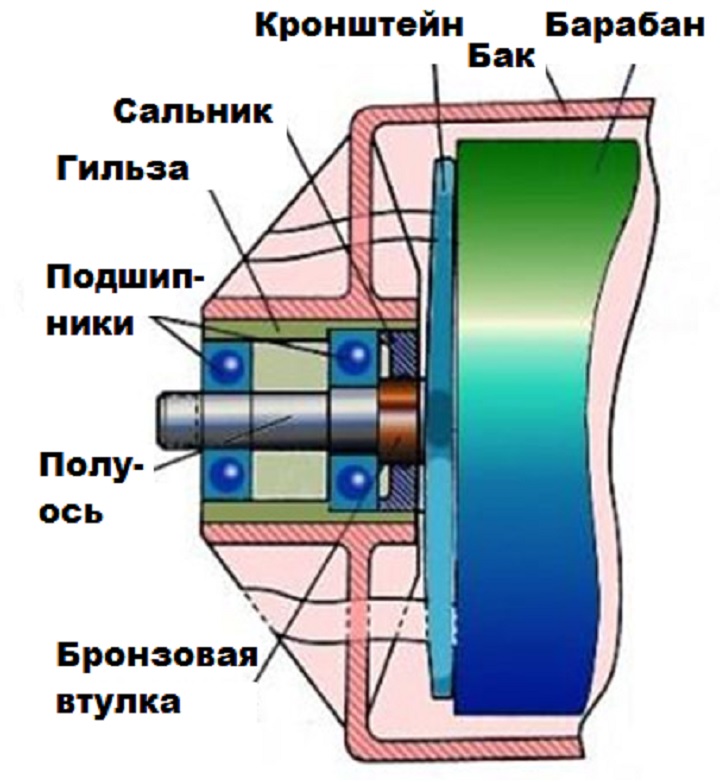

SMA bearings last on average up to 7 years, and in case of violation of operating conditions (drum overload, improper installation) - even less. Doing it yourself is difficult. Such repairs are best entrusted to the master.

To make sure that the cause of the trouble with the SMA lies in the bearings - open the loading door and try to scroll the drum by hand. If you manage to do this with difficulty, the drum spins unevenly - the problem is in the bearings.

Internal elements of the washing machine: bearings, bushings, oil seals

How to check the counterweight of the washing machine?

Counterweights are fixed on the SMA tank and are designed to damp vibrations. In fact, this is a weighting agent. They can be made both from concrete and from cast iron. The latter practically do not break, concrete can crumble (but this also happens very rarely). But sometimes the mounting of the counterweights can loosen.

Depending on the specific model of technology, the balances can be mounted in different places: from above, from the front or from the back.

To check the items you need:

- Remove the cover by unscrewing the screws.

- Inspect the attachment points of the balances, tighten them if necessary.

- If the concrete counterweight has crumbled, it must be replaced with a new one.

Shock absorbers and dampers

If there is a very strong vibration during the spin cycle in the washing machine, be sure to check the dampers and shock absorbers.

To check the fault:

- Remove the front and back cover.

- To check the springs, push your hands on the CMA tank, if it quickly falls into place - everything is in order, if not - conduct a thorough inspection of the parts and replace if necessary.

- Dampers are located below the tank, carefully examine them.

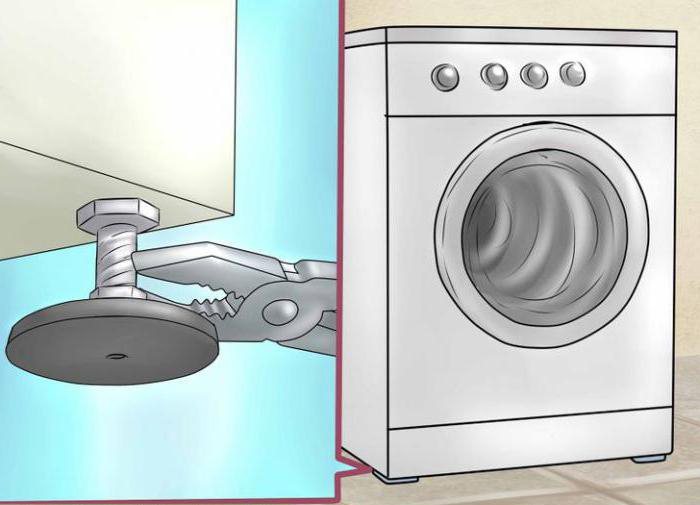

- To remove the damper, unscrew the lower fastener of the part, fix the damper sleeve in the upper part with a nut (this helps to remove the locks), pull out the sleeve using pliers. After that, you can safely change the part to a new one.

Washing machine dampers

Shock absorbers for the washing machine

Electric motor

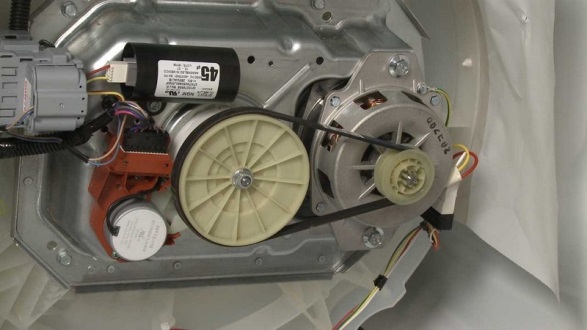

The most annoying and very expensive damage. In some cases, repair is not practical (for example, if you have had equipment for more than 10 years, other parts are probably worn out there, and such a machine is outdated), it’s easier to buy another SMA.

But do not rush to panic. Strong vibrations during operation may indicate a weakening of the engine mount. In this case, just remove the cover., adjust and fix the engine mounting bolts.

Electric drive СМА

Water flows strongly during spin

Another common problem that can cause a lot of trouble not only to owners of AGR, but also to their neighbors. If you saw that water flows from the machinecheck the following:

- Is the drain hose correctly inserted into the riser?

- if there is any blockage in the sewer;

- inspect the drain hose for cracks and other damage, check the mounting of the clamps;

- Check the integrity of the door seal.

As you can see, there are many reasons why the washing machine vibrates, jumps, and makes extraneous noises, as well as a lot of reasons. Some can be fixed independently, others - only with the help of masters. Remember that many troubles can be avoided by following the manufacturer's recommendations. Install the machine by level, do not overload it, check the pockets of clothes before loading - your equipment will last much longer and will delight you with reliable and trouble-free operation!